High-Precision, High-Speed Pizza Production by Hengjiang Intelligent Technology Co., Ltd.

As global demand for frozen pizza, fresh dough pizza, and ready-to-bake pizza bases continues to surge, food manufacturers are under increasing pressure to scale production without compromising consistency, hygiene, or flexibility. The Automatic Pizza Forming Line by Hengjiang Intelligent Technology Co., Ltd. is engineered to meet these demands head-on, delivering industrial-grade automation, exceptional forming accuracy, and food-safe design for modern pizza production facilities.

Automatic Pizza Forming Line

Designed for high-volume, continuous operation, this advanced pizza forming solution supports manufacturers aiming to optimize labor efficiency, ensure repeatable quality, and adapt quickly to changing market trends such as customized pizza sizes, clean-label processing, and smart factory integration.

Precision-Driven Pizza Forming for Consistent Quality

At the core of the Hengjiang Automatic Pizza Forming Line is a high-precision forming system that ensures every pizza base meets exact specifications for diameter, thickness, and weight uniformity. Whether producing traditional round pizza crusts, thin-crust styles, or thicker pan-style bases, the line maintains stable output even at high operating speeds.

This level of precision is especially critical for:

Frozen pizza manufacturers

Central kitchens

Large-scale bakery and food processing plants

Private-label pizza brands requiring strict portion control

Uniform dough forming not only improves visual consistency but also ensures even baking performance, reducing waste and enhancing end-consumer satisfaction.

High-Speed, High-Capacity Automation

Built for industrial throughput, the Automatic Pizza Forming Line supports continuous, high-capacity production without sacrificing reliability. Advanced motion control and synchronized forming modules enable stable operation at high speed, making the line ideal for mass production environments.

Key performance benefits include:

Continuous automated operation with minimal downtime

Stable output during long production shifts

Reduced reliance on manual labor

Improved overall equipment effectiveness (OEE)

By automating critical forming stages, manufacturers can significantly lower labor costs while increasing daily output — a key advantage in today’s competitive food manufacturing landscape.

Flexible Production for Multiple Pizza Sizes and Styles

Responding to growing consumer demand for variety and customization, the Hengjiang pizza forming line is designed with exceptional flexibility. The system supports multiple pizza diameters and dough formats, allowing quick adjustments to meet diverse product requirements.

This flexibility makes the line suitable for producing:

Mini pizzas and snack-size bases

Standard retail pizza crusts

Family-size or extra-large pizza bases

Customized specifications for foodservice clients

Tooling and parameter adjustments are optimized for fast changeovers, enabling manufacturers to switch product formats efficiently and respond quickly to market trends.

Hygienic Design for Food Safety Compliance

Food safety is a top priority in modern pizza production, and Hengjiang’s Automatic Pizza Forming Line is built to meet stringent hygiene standards. The equipment features a hygienic structural design that minimizes contamination risk and simplifies cleaning and maintenance.

Hygiene-focused design elements include:

Food-grade stainless steel construction

Smooth surfaces with minimal crevices

Easy disassembly for cleaning and sanitation

Compliance with international food processing standards

This design supports compliance with HACCP, GMP, and other food safety protocols, making the line suitable for export-oriented production and multinational brands.

Smart Manufacturing and Easy Operation

Aligned with current Google-trending topics such as smart manufacturing, industrial automation, and intelligent food processing, the Automatic Pizza Forming Line is designed for user-friendly operation and system integration.

The intuitive control interface allows operators to:

Monitor production parameters in real time

Adjust forming settings with precision

Ensure stable operation with minimal training

The system can also be integrated into broader automated pizza production lines, connecting seamlessly with dough preparation, topping application, baking, freezing, and packaging systems.

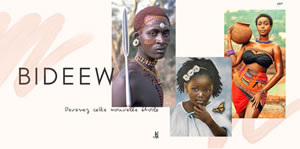

Devenez cette étoile ★ (bideew), faites de nouvelles rencontres sur la plus grande communauté en Afrique et partagez vos meilleurs moments avec vos proches

Devenez cette étoile ★ (bideew), faites de nouvelles rencontres sur la plus grande communauté en Afrique et partagez vos meilleurs moments avec vos proches