During which industries is Hydraulic Shop Press most traditional?

With its powerful pressure and precise control capabilities, Hydraulic Shop Press plays an important role in many industries. This equipment converts the pressure energy in the liquid into mechanical energy via a hydraulic transmission system to quickly attain fast and stable force processing of workpieces or perhaps materials.

1. Automobile Manufacturing Industry

In the car or truck manufacturing industry, the application of Hydraulic Shop Push is ubiquitous. From entire body stamping, component forming for you to engine assembly, this products has played an key role. In the manufacturing technique of automobile bodies, Hydraulic Shop Press is mainly used for stamping along with forming operations. Various elements of the car body, just like doors, hoods, roofs, etc.,need to be precisly stamped and formed. Hydraulic Shop Press provides stable pressure and precise control to ensure that the size, shape and surface quality of each one part meet the pattern requirements. Automobiles are constructed from thousands of parts, many of which has to be processed by Hydraulic Look Press. For example, motor brackets, suspension system areas, brake system parts, for example.,all need to possibly be precisely stamped, pressed or even formed on Hydraulic Buy Press. The precision and stability of this equipment ensure the dimensional correctness and mechanical properties in the parts, thereby ensuring the general quality and performance with the car. Hydraulic Shop Press also plays a significant role in the welding and assembly approach to the car. For model, during the welding process, Hydraulic Shop Press may be used to clamp and position the workpiece to make certain the accuracy and stability on the welding position. During your assembly process, Hydraulic Shop Press is known to apply the necessary preload to be sure a tight fit plus stable connection between segments.

2. Aerospace Industry

In the aerospace industry, the requirements to the strength, toughness and accurate of materials are particularly high. Hydraulic Shop Hit can meet these specific needs through its highly accurate pressure control and successful pressure output. In the manufacturing and assembly means of aircraft parts, Hydraulic Buy Press can ensure the accuracy and stability regarding parts, providing a strong guarantee for the introduction of the aerospace industry.

3 OR MORE. Mold Manufacturing Industry

Form manufacturing is another necessary application field of Hydraulic Store Press. The precision and durability from the mold directly affect the coffee quality and production efficiency from the product. Hydraulic Shop Media can achieve fast and also precise pressing of molds by its efficient and secure pressure output, ensure the product quality and durability of molds, plus meet the manufacturing industry's need for high-precision molds.

4. Metal processing industry

Hydraulic Shop Press also plays a key role in the sheet metal processing industry. Whether it really is metal stamping, stretching or perhaps forming, strong pressure and precise control are needed. Hydraulic Shop Press can certainly meet these needs and offer efficient and stable processing equipment for the metal processing industry. As well, its efficient working pressure may also reduce energy consumption and production costs and develop production efficiency.

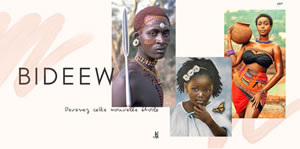

Devenez cette étoile ★ (bideew), faites de nouvelles rencontres sur la plus grande communauté en Afrique et partagez vos meilleurs moments avec vos proches

Devenez cette étoile ★ (bideew), faites de nouvelles rencontres sur la plus grande communauté en Afrique et partagez vos meilleurs moments avec vos proches