In the dynamic landscape of manufacturing, Plastic Injection Mould Manufacturers and Forging Mold Manufacturers play pivotal roles in shaping the production processes across various industries. This article delves into the nuanced world of these manufacturers, examining their methods, applications, and the significance they hold in the manufacturing sector.

:

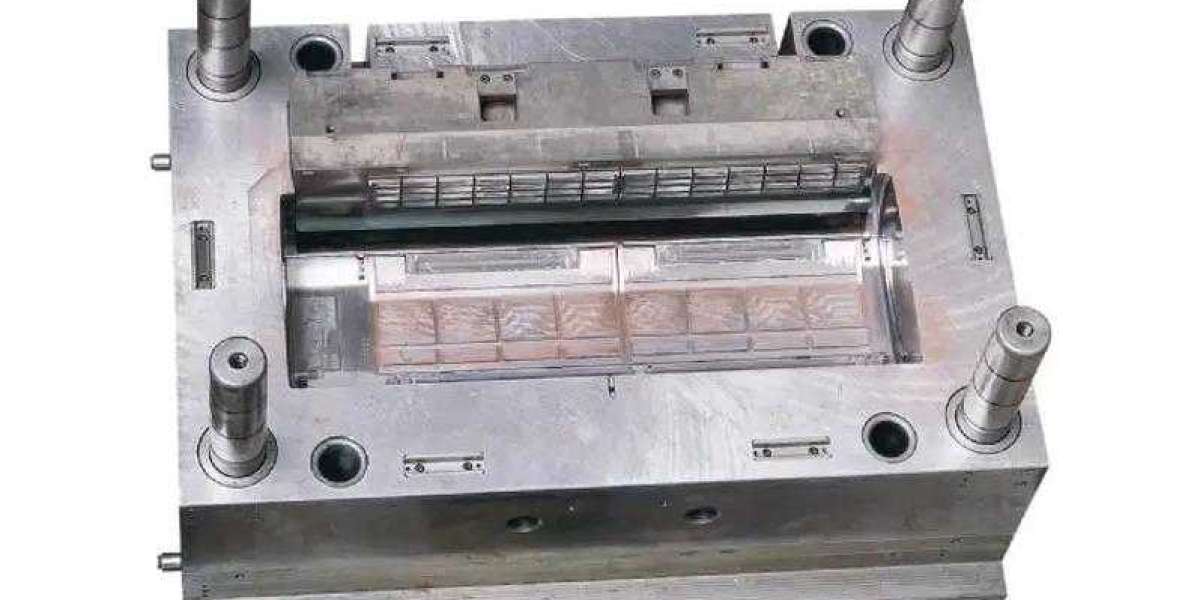

Plastic injection molding has emerged as a cornerstone in the manufacturing realm, allowing for the efficient production of a wide array of plastic components. Plastic Injection Mould Manufacturers specialize in creating molds that facilitate the shaping of molten plastic into precise forms. These molds, crafted with precision and attention to detail, serve industries ranging from automotive and consumer goods to electronics and medical devices.

The expertise of Plastic Injection Mould Manufacturers lies in their ability to design and fabricate molds that meet the specific requirements of diverse applications. This includes intricate geometries, complex structures, and varying sizes. The molds undergo rigorous testing to ensure durability and consistency in the molding process. These manufacturers continuously innovate, adopting advanced materials and technologies to enhance the efficiency and life cycle of their molds.

Forging Mold Manufacturers:

In the realm of metalworking, Forging Mold Manufacturers play a crucial role in the production of forged components. Forging molds are instrumental in shaping metal through a process that involves applying pressure to deform the material into the desired form. This method is widely employed in the aerospace, automotive, and energy sectors, where the strength and integrity of forged components are paramount.

are skilled craftsmen who design and fabricate molds capable of withstanding the immense forces involved in the forging process. The durability and precision of these molds are critical factors that directly impact the quality of the forged components. From simple shapes to intricate designs, forging molds are tailored to meet the specific needs of each application.

Applications Across Industries:

Both Plastic Injection Mould and Forging Mold Manufacturers contribute significantly to various industries, albeit in different ways. Plastic injection molding finds applications in the mass production of plastic components used in everyday items, electronic devices, and automotive parts. Forging molds, on the other hand, are integral to the production of high-strength metal components used in critical applications, such as aircraft parts, automotive components, and industrial machinery.

Continuous Innovation:

The world of mold manufacturing is marked by a spirit of continuous innovation. Plastic Injection Mould and Forging Mold Manufacturers are at the forefront of adopting new materials, technologies, and design methodologies. This commitment to innovation enables them to meet evolving industry demands, enhance the performance of molds, and contribute to the overall efficiency of manufacturing processes.

In conclusion, Plastic Injection Mould Manufacturers and Forging Mold Manufacturers are indispensable contributors to the manufacturing landscape. Through their expertise in crafting precision molds, these manufacturers enable the efficient production of plastic and metal components that form the backbone of various industries. Their commitment to innovation ensures that manufacturing processes evolve to meet the challenges of an ever-changing industrial landscape. As key players in the manufacturing ecosystem, these manufacturers exemplify proficiency, adaptability, and a dedication to pushing the boundaries of what is achievable in the world of mold manufacturing.