Progressive Cavity Pumps No Match for Electric Diaphragm Pumps

For industrial fluid transfer applications, progressive cavity pumps have long been a popular choice due to their ability to handle thick, viscous materials. However, their mechanical design comes with disadvantages that electric diaphragm pumps can overcome. Let's examine why electric diaphragm pumps now provide a better solution for many processes.

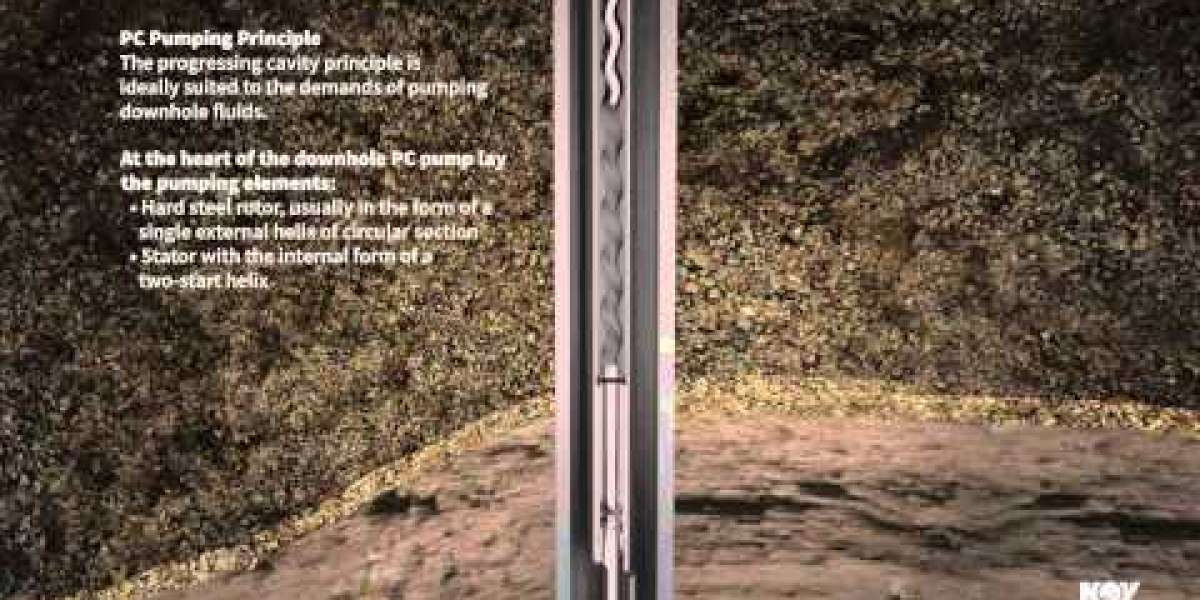

How Progressive Cavity Pumps Work

Progressive cavity pumps, also called progressive cavity metering pumps or PC pumps, use a helical rotor inside a matching helical stator. As the rotor turns, cavities are formed to transfer fluid in a controlled manner. While effective for high-viscosity fluids, issues arise from their mechanical seal and inability to run dry.

Issues with Progressive Cavity Pumps

Some major disadvantages of include expensive seals vulnerable to wear, contamination risks, and the inability to run dry without damage. Their complex design also makes them large, energy-inefficient, and difficult to maintain versus simpler diaphragm pump technology.

Electric Diaphragm Pump Operation

Unlike , electric diaphragm pumps like Graco's QUANTM use a direct-acting, non-wetted diaphragm and electric motor. Fluid is transferred through the diaphragm's oscillating action rather than mechanical components, providing major benefits.

Advantages of Electric Diaphragm Pumps

Seal-less Design

Eliminating mechanical seals removes leak points and contamination concerns. Diaphragm pumps can also run dry indefinitely without harm.

Lower Energy Usage

Their efficient electric motor integration yields energy savings up to 5x over progressive cavity pumps.

Simpler Operation

Without a mechanical drive, diaphragm pumps have fewer wear parts for reduced downtime and simpler maintenance.

Stall Protection

QUANTM pumps safely stall under pressure without damage using their compressed air-free design.

Compatibility

Diaphragm pumps are suitable for a wide variety of aqueous and non-aqueous liquids handled by progressive cavity pumps.

Smaller Footprint

Compact electric diaphragm pumps require less space than larger progressive cavity pumps.

Industry Applications

Areas where electric diaphragm pumps outperform progressive cavity pumps include water/wastewater treatment, pharmaceuticals, chemicals, coatings, lubricants, food/beverage, and more.

For precision fluid transfer needs, electric diaphragm pumps offer multiple advantages over progressive cavity pumps. Their superior design provides higher reliability, lower costs, and increased safety to maximize process uptime.