are widely used in the electronics industry for establishing secure connections between wires and printed circuit boards (PCBs). These connectors are favored for their ease of use and reliability, making them an essential component in many electronic assemblies.

The crimping process involved in these connectors allows users to create a strong mechanical bond without the need for soldering. This not only speeds up the assembly process but also reduces the risk of damage to the wires or PCB. Users can achieve consistent and reliable connections by simply inserting the stripped wire into the connector and using a crimping tool.

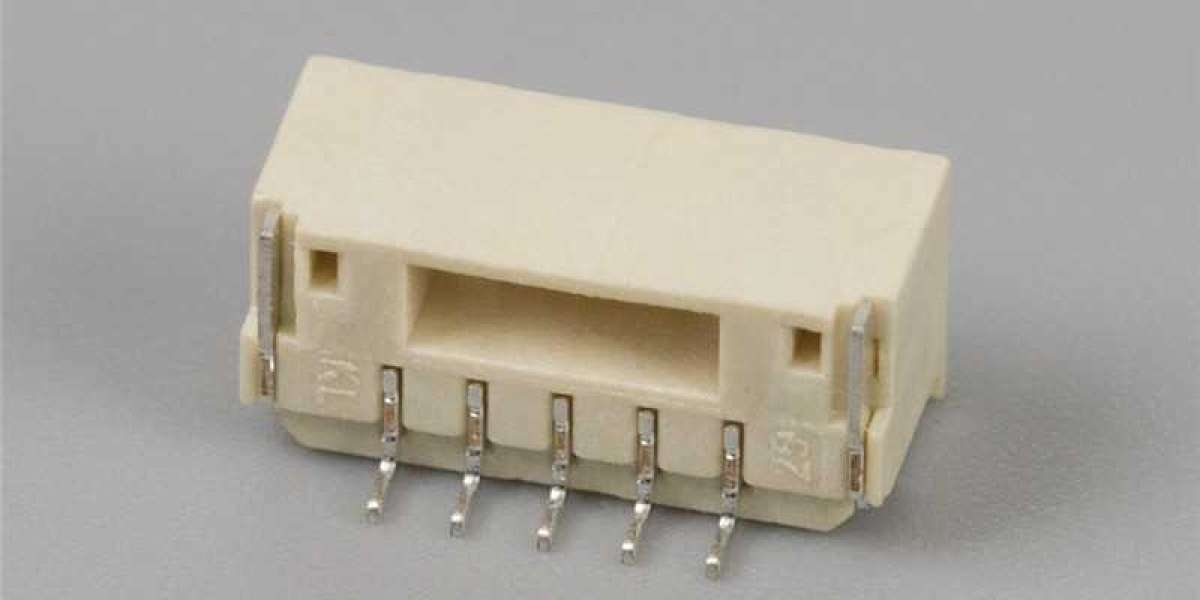

Manufacturers focus on producing crimp style connectors that are durable and resistant to various environmental factors. Many connectors are designed to withstand vibrations, temperature changes, and moisture, ensuring that they maintain their performance over time. Some models also incorporate locking features to prevent accidental disconnections.

These connectors come in a range of sizes and configurations, making them adaptable to various applications, from consumer electronics to automotive and industrial systems. The versatility of wire to board crimp style connectors enables engineers to choose the right solution for their specific needs.

In summary, provide a reliable and efficient method for creating secure connections in electronic assemblies, supporting a wide range of applications across different industries.