The manufacturing of involves a combination of precision engineering and material selection to ensure durability and effectiveness. These drains are typically made from materials that can withstand the elements, such as stainless steel, cast iron, or high-quality plastics, which are chosen for their resistance to corrosion and their ability to maintain structural integrity over time.

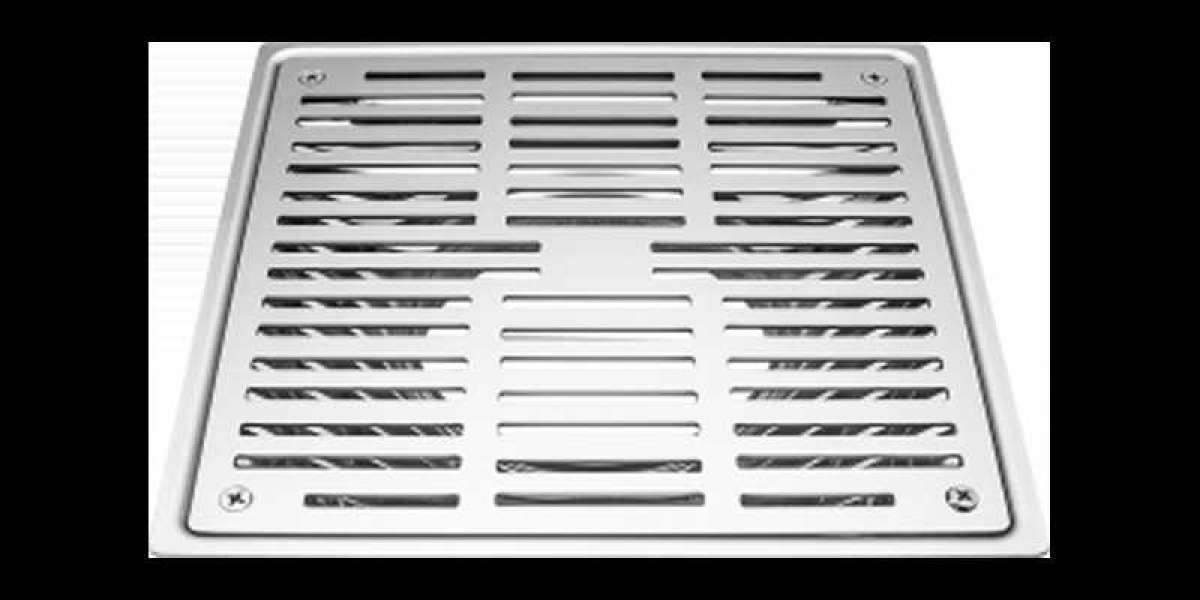

During the manufacturing process, attention is given to the design of the drain's grate or cover to ensure it is both visually appealing and functional. The grate must be strong enough to support the weight of pedestrians and furniture while allowing water to pass through easily. Some manufacturers incorporate anti-clog features into the design, using fine meshes or screens that prevent debris from entering the drain while still allowing water to flow freely.

The manufacturing process also involves creating a watertight seal between the drain body and the surrounding surface. This is crucial to prevent water from seeping into the building structure or causing damage to the terrace flooring. High-quality seals and gaskets are used to ensure a snug fit and a long-lasting, leak-free connection.

In summary, the manufacturing of terrace floor drains requires a careful balance of material science, engineering, and design to produce a product that is both functional and durable, capable of withstanding the test of time and the elements.