The production of WPC flush doors(https://www.homely-doors.com/) has gained significant attention in the construction and interior design industries due to their durability, aesthetic appeal, and eco-friendliness. The manufacturing process of these doors is a sophisticated blend of material science and advanced engineering, ensuring that the final product meets high-quality standards.

The journey of a WPC flush door begins with the careful selection of raw materials. The primary components include wood powder, plastic pellets, and various additives. These materials are meticulously weighed and mixed according to specific formulations to create a composite that combines the best properties of wood and plastic. This initial step is crucial as it lays the foundation for the door's strength and durability.

Once the raw materials are prepared, the next phase involves extrusion. In this process, the mixed materials are fed into an extruder, where they are heated and forced through a die to form the basic shape of the WPC flush door panel. This method not only shapes the door but also ensures that the materials are uniformly distributed, which is vital for maintaining structural integrity.

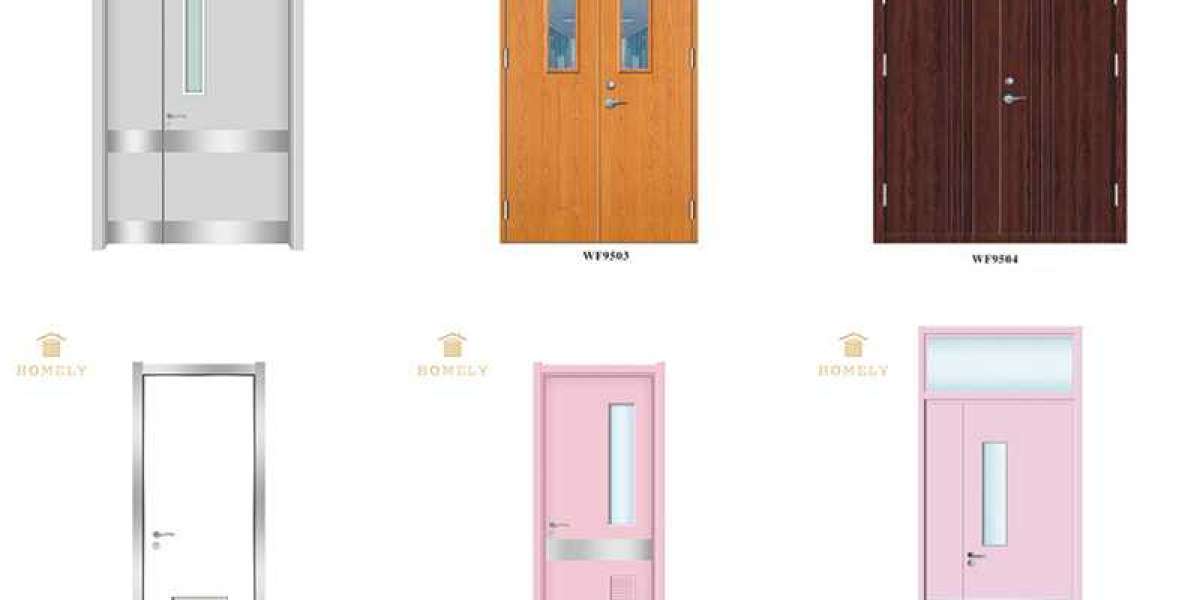

After extrusion, the panels undergo a series of treatments to enhance their quality. Sanding is performed to create a smooth surface, which is essential for the aesthetic appeal of the WPC flush door. Following sanding, the panels may be laminated or coated with a protective film to improve their resistance to moisture, UV rays, and other environmental factors. This step is particularly important as it contributes to the longevity of the doors, allowing them to withstand daily wear and tear.