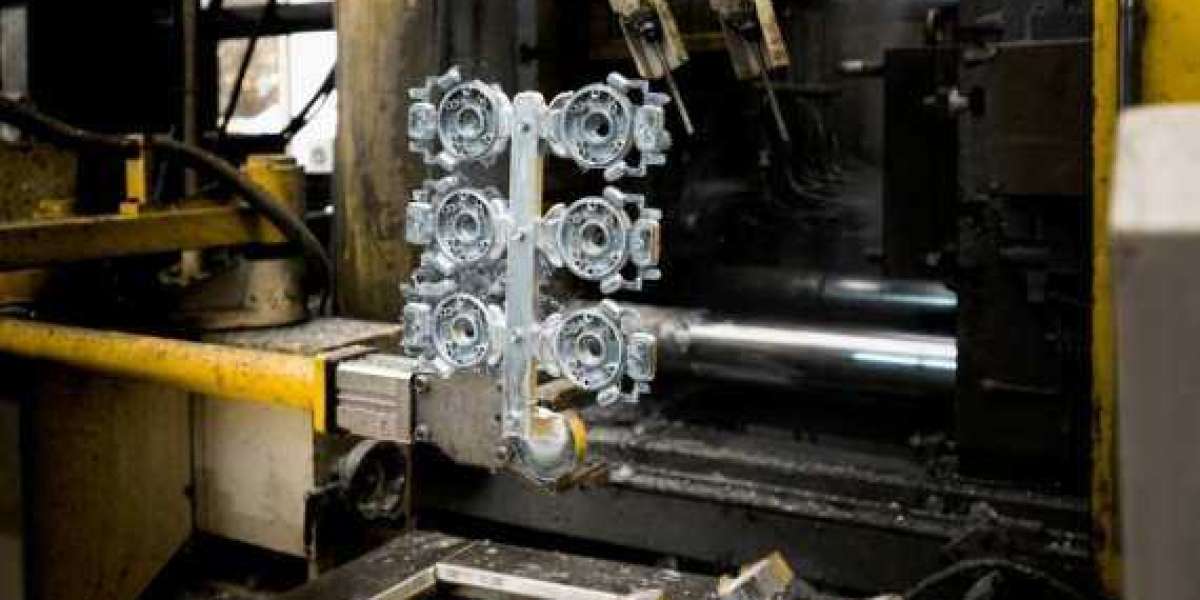

After the metal die-casting process has been finished, impressions will continue to be left on the hook in the location where the plated part was attached. The location of the component can then be determined using this. Your undivided attention is required for this, as it is one of the most important aspects of the situation. Because the hook is getting wider, the proportion of the plated part that is going to be covered by it is going to increase. This is going to have an effect that is direct on the normality of the layer at this point in time because it is going to have an effect on the proportion of the plated part that is going to be covered.

By simply snapping it off, the hook can be removed with very little effort required on the user's part. In particular, the coating that is located at the point of contact, which is the location where the hook immediately hangs the product workpiece, will be extremely thin, whereas the coating that surrounds the point of contact will be thick. This is because the point of contact is the location where the hook immediately hangs the product workpiece. It is going to malfunction, putting everyone in a precarious circumstance that may put their lives in jeopardy.

In addition to increasing the thickness of the coating that is on the hanger, simultaneously increasing its area correspondingly, increasing the amount of metal material that is on the sink, and increasing the amount of solution that is produced by the hanger are all factors that contribute to an increase in the cost of the product, while simultaneously increasing the amount of electric energy that is used. The thickness of the coating that is applied to the hanger is significantly higher than is acceptable. The coating's surface currently possesses a higher level of roughness; however, as a direct consequence of this change, the coating's ability to be cleaned has significantly diminished.

There is a possibility that the method used to remove the plating layer from the hanger can be the same method that was used to remove the plating from the plating part. Because of this, the procedure for removing the general type of plating can remain the same. When you use the wire cutter again, the coating may flake off on its own in some instances. In some circumstances, however, it might not. After the precious metal plating rack has been removed, the solution that contains precious metals should be managed in the appropriate manner in order to ensure that it can be recycled in the event that this becomes necessary in the future.

If the hanger that was used for aluminum oxidation is used more than once to carry out the film stripping treatment, it will no longer be able to pass through the conductive flow. This will happen if the treatment is carried out more than once. This result is to be expected if the treatment is administered on more than one occasion. In the event that this transpires, it will not be possible to carry out the treatment. When the film is stripped using the acid-alkali stripping solution, the substrate will not be eroded after the film layer has been removed. As a result, an increased number of hanging tools can be used after the film has been stripped. length of time required to submit an applicationIn addition, you can use a file to smooth the surface of the component that is in contact with the product and is the location of the oxide film. This is in addition to the two different methods of film removal that were covered earlier in the preceding discussion. After the necessary documentation has been handed in, you will be able to make use of it.

Unreasonable loading and unloading, as well as removal, can frequently be traced back to being one of the most important causes of the damage that has been done to the mold throughout the entirety of the process of maintenance and removal. This is because removal is one of the most important steps in the process. When it comes to cleaning die splices, whetstones and metallographic sandpaper are two of the most effective tools to use. When you are performing the routine maintenance on the water storage tank, you need to make sure that each of the four sides of the conventional block is in the correct position. This is an important step in the process. As a consequence of this, you will have the ability to make adjustments that are appropriate for the indoor location that is devoted to the activity. It is against the law to include the mold in the same inventory as the corroded product, and after the mold has been used, it needs to be cleaned, then it needs to be put back together, and then it needs to be cleaned some more. If mold is to be preserved, it needs to be kept in a warehouse that is spotlessly clean, completely dry, and provides adequate natural ventilation.

The life of a die casting die is significantly impacted not only by the material of the die, but also by the heat treatment that the material undergoes.

If a mold's lifetime can be extended for an additional period of time, this will result in a reduction in the associated costs. The mold has a low quality, and its service life is only one fifth to one half of what it was in the excellent my country. Despite this, the current service life of the mold also has higher advantages for society as well as the economy, in addition to increased levels of competitiveness. the indoor space.

The specifications for the molds call for them to have a higher level of quality, to be of a large type, and to have a quicker delivery time, respectively. These are all concise descriptions of the various types of molds. The kind of mold, the specifications of the mold, and the level of quality of the mold are all factors that have a direct bearing on how well the mold will function over the course of its lifetime and how long it will continue to be useful.

In addition to the efficient design of the structure of the mold, it is also important to select appropriate mold materials and heat treatment techniques in order to better enable the mold to achieve excellent application performance and a long service life. This can be achieved through the use of the mold. Because of this, the individual utilizing the mold will have a much simpler time accomplishing the goals they have set for themselves when using the mold. At this stage, the arrangement of mold materials and the performance of mold materials are improved according to heat treatment. This is achieved through the application of new materials and the gradual improvement of mold production technology. In addition, a large number of new materials have been developed that are easy to work with and perform exceptionally well when subjected to heat treatment. The primary heat treatment that was applied in the beginning serves as the foundation for the brand-new and significantly enhanced method. As a result of the implementation of a number of different technological advancements, the mold's expected lifetime has been significantly extended. The development potential of mold materials can be fully utilized thanks to effective material selection, the selection of new mold materials, and the implementation of appropriate and excellent heat treatment technology. This enables full utilization of the development potential of mold materials. Because of this, the full development potential of the mold materials can be utilized. This makes it possible to improve the application performance of molds, and it also makes it possible to increase the life of molds by several times or even dozens of times over their original lifespan.